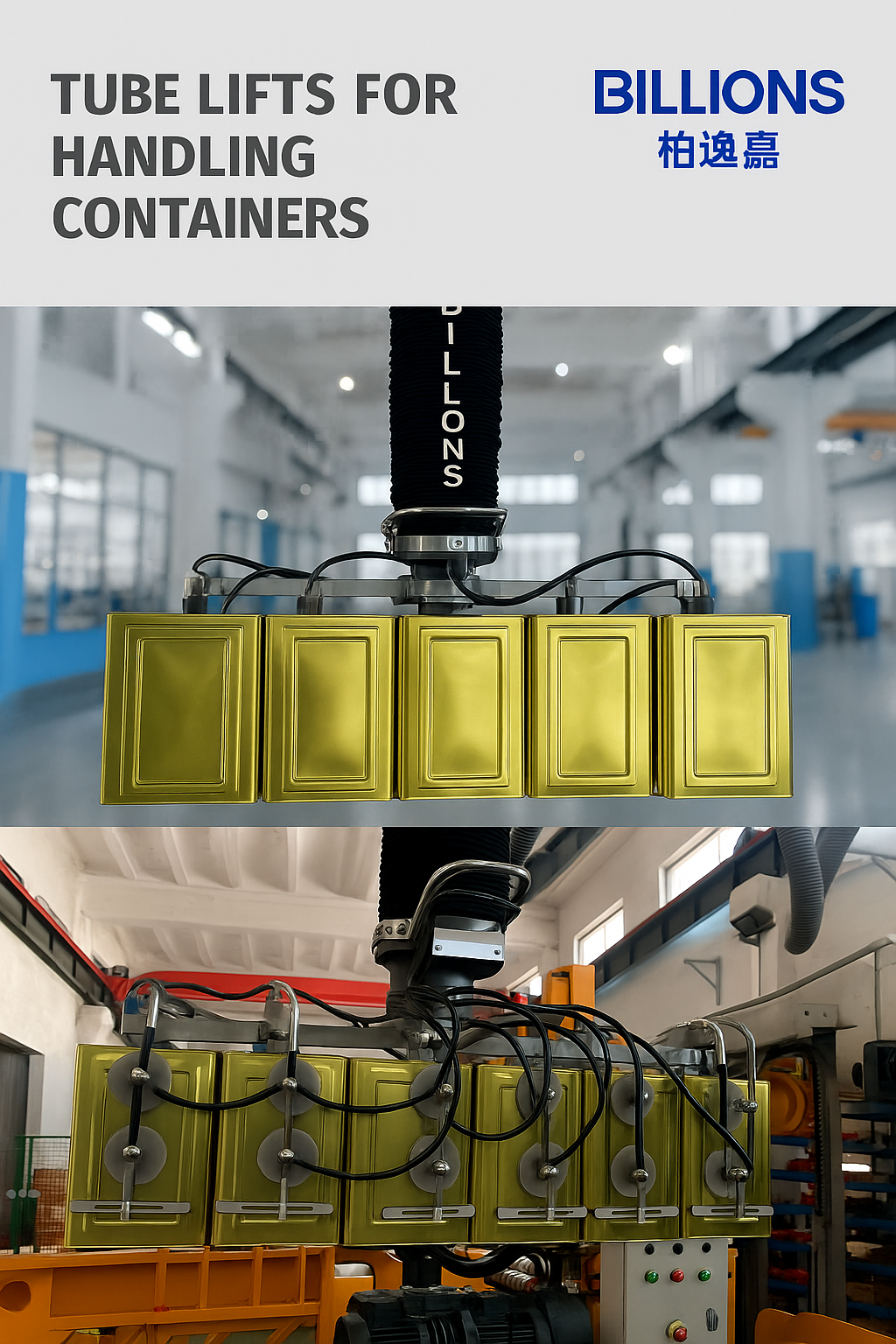

BILLIONS Vacuum Tube Lifter For Drum Handing

Easy Control One time handing for five Tin Cans Safety Loading 60kgs

BILLIONS Vacuum Tube Lifter Boosts Safety and Efficiency for a Korean Chemical Plant

Customer Challenges & Operating Environment

Special Cargo Requirements:

The goods consist of five rectangular tin cans containing liquid adhesive sealed in plastic liners. Each batch weighs 55 kg, demanding stable, spill-free handling throughout the transfer.

Harsh Working Conditions:

The workflow involves moving from outdoor areas into indoor facilities. During Korea’s winter peak season, low temperatures posed challenges to equipment reliability and suction performance.

Operator Fatigue and Safety Risks:

Repetitive manual handling of heavy loads caused strain and potential musculoskeletal injuries for workers.

Need for Flexible Operation:

The client required a system adaptable to operators of different heights and capable of maneuvering easily along a dynamic transport route.

BILLIONS Customized Handling Solution

Powerful Vacuum Generation:

A custom high-power vacuum blower ensures consistent suction even in sub-zero temperatures, maintaining strong, stable lifting force.

Specialized Suction Cups:

Equipped with 10 silicone vacuum pads specifically designed for rectangular tin cans. The soft, cold-resistant silicone material tightly conforms to the surface, preventing slippage during transport.

Comprehensive Safety Protection:

Multi-layer safety systems allow the lifter to maintain suction even during power loss, preventing accidental drops and guaranteeing maximum operator and product safety.

2️⃣ High Efficiency and Mobility

Portable and Flexible:

The mobile base allows seamless operation between outdoor filling and indoor packaging zones—no installation constraints.

Precise Floating Control:

The BILLIONS vacuum tube lifter features a smooth, adjustable float mode, enabling the operator to suspend and position the load at any height—ideal for workers of varying heights.

3️⃣ Ergonomic, Operator-Friendly Design

True Weight-Free Handling:

The lifter bears the full 55 kg load. Operators guide the movement effortlessly with minimal physical effort, eliminating back strain and improving long-term ergonomics.

4️⃣ Reliable After-Sales Support

The client purchased a complete set of spare parts, including vacuum pads and filters, ensuring long-term operational stability. BILLIONS provides continuous support and fast spare-part supply worldwide.

5️⃣ Tailored Engineering for Every Scenario

Each BILLIONS vacuum lifting system can be customized for unique materials, environments, or lifting angles—a truly personalized solution for every industrial application.

By introducing the BILLIONS TB-VAT-180 Vacuum Tube Lifter, the Korean chemical plant successfully transformed its manual heavy-load process into a modern, safe, and efficient material-handling workflow.

The upgrade eliminated safety risks, reduced worker fatigue, and significantly improved logistics efficiency and overall productivity.

With over a decade of expertise in safe, efficient, and ergonomic vacuum handling systems, BILLIONS empowers manufacturing and logistics teams worldwide to move smarter and safer.